Introduction

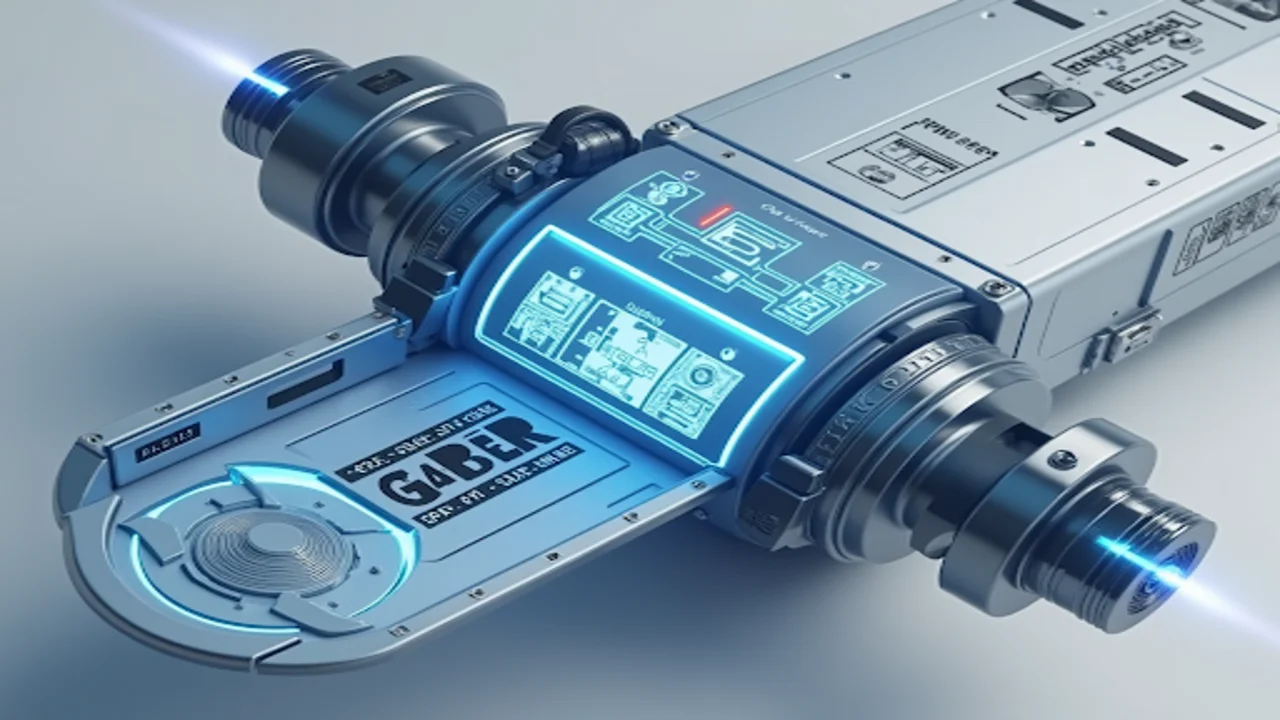

In the rapidly evolving world of industrial automation, precision, reliability, and efficiency are paramount. The Butler G4B25, a groundbreaking mechanical component, has emerged as a key player in this domain, transforming operations across various industries. Renowned for its robust design, precision engineering, and unparalleled versatility, the Butler G4B25 is a cornerstone in enhancing productivity and operational excellence. This article delves into the intricate details of the Butler G4B25, highlighting its design, applications, advantages, and maintenance requirements.

What Is the Butler G4B25?

The Butler G4B25 is a state-of-the-art industrial component designed to facilitate precise and controlled movements in automated systems. Built to endure heavy-duty operations, it integrates seamlessly into various machinery, enhancing efficiency and reliability. From assembly lines to CNC machines, its applications span a wide array of industries, making it indispensable in modern manufacturing.

The G4B25 excels in environments requiring high strength and flexibility, with its adjustable swing radius, customizable attachments, and smooth rotational motion setting it apart from other components. Its versatility and robust performance have earned it a reputation as a reliable asset in industrial automation.

Key Features of the Butler G4B25

Precision Engineering for Accuracy

The Butler G4B25 is engineered with meticulous precision, enabling accurate positioning and movement. This makes it ideal for applications demanding exact measurements, such as CNC machining and robotic assembly.

Adjustable Swing Radius for Versatility

A standout feature of the G4B25 is its adjustable swing radius, which allows it to adapt to varying operational requirements. This flexibility enhances its usability across multiple applications, from confined spaces to expansive assembly lines.

Customizable Attachments for Specialized Tasks

The G4B25 supports a range of customizable attachments, enabling it to perform specialized tasks. Whether it’s lifting, rotating, or gripping, this feature broadens its scope of use and ensures compatibility with diverse industrial needs.

High Load Capacity for Heavy-Duty Operations

Designed with durability in mind, the Butler G4B25 can handle substantial loads without compromising performance. Its high-strength construction makes it a reliable choice for heavy equipment operations.

Smooth Rotational Motion for Efficiency

The component’s capability for smooth rotational motion ensures efficiency in material handling and other operations. This reduces wear and tear on connected machinery and minimizes downtime.

Applications of the Butler G4B25

Assembly Lines in Manufacturing

The G4B25’s precision and flexibility make it invaluable in assembly line operations. It facilitates seamless movement and positioning of components, streamlining production processes and improving output quality.

Material Handling for Logistics

In logistics, the G4B25 simplifies the handling and transfer of materials. Its smooth motion and high load capacity reduce reliance on manual labor, enhancing efficiency and safety.

Robotic Systems for Advanced Automation

As a critical component in robotic arms, the Butler G4B25 enables complex movements essential for tasks like welding, packaging, and precise assembly. Its adaptability ensures optimal performance in advanced automation systems.

CNC Machining for Enhanced Accuracy

In CNC machining, the G4B25 assists in the accurate positioning of workpieces. Its precision ensures high-quality machining outcomes, reducing errors and waste.

Automotive Manufacturing for Large-Scale Production

The automotive industry benefits significantly from the G4B25’s strength and precision. It handles large automotive parts with ease, enhancing production line efficiency and reducing cycle times.

Advantages of Using the Butler G4B25

Improved Operational Efficiency

The integration of the G4B25 into automated systems accelerates production cycles, leading to higher output rates and consistent product quality.

Reduced Labor Costs

By automating repetitive and labor-intensive tasks, the G4B25 minimizes the need for manual intervention, resulting in significant cost savings.

Enhanced Precision and Reliability

The component’s advanced engineering ensures reliable and precise performance, reducing errors and enhancing the overall quality of industrial operations.

Versatility Across Industries

With its adjustable features and customizable attachments, the G4B25 is adaptable to a wide range of tasks, making it a versatile addition to any industrial setup.

Durability for Long-Term Use

Constructed from high-strength materials, the G4B25 is built to last, providing long-term value and reducing the need for frequent replacements.

Comparison with Competitors

| Feature | Butler G4B25 | Competitor A | Competitor B |

| Load Capacity | High | Medium | High |

| Adjustable Swing Radius | Yes | No | Limited |

| Customizable Attachments | Extensive | Basic | Extensive |

| Rotational Motion | Smooth | Standard | Smooth |

| Durability | High-Strength Materials | Standard Materials | High-Strength Materials |

Maintaining the Butler G4B25

Regular Inspections for Wear and Tear

To ensure optimal performance, inspect the G4B25 regularly for signs of wear. Early detection of issues can prevent costly repairs and downtime.

Lubrication of Moving Parts

Proper lubrication reduces friction, extending the lifespan of the component. Use recommended lubricants to maintain smooth operation.

Secure Fastening of Components

Check that all parts are securely fastened to prevent loosening during operation. This ensures safety and reliability in high-stress environments.

Adherence to Maintenance Schedules

Following a consistent maintenance schedule prolongs the G4B25’s lifespan and ensures uninterrupted performance.

Professional Servicing When Needed

For complex repairs or replacements, rely on professional servicing to maintain the integrity of the component.

FAQs About the Butler G4B25

1. What industries benefit most from the Butler G4B25?

Industries such as automotive manufacturing, industrial automation, and heavy equipment operations find the G4B25 invaluable due to its versatility and precision.

2. Can the Butler G4B25 handle high-load applications?

Yes, the G4B25 is engineered to support substantial loads, making it suitable for demanding industrial environments.

3. How does the Butler G4B25 enhance CNC machining accuracy?

Its precision engineering ensures accurate positioning of workpieces, leading to high-quality machining outcomes.

4. What makes the G4B25 durable for industrial use?

The use of high-strength materials in its construction ensures durability and resilience in challenging conditions.

5. How often should the Butler G4B25 be maintained?

Regular maintenance, including inspections and lubrication, is recommended to ensure optimal performance and longevity.

Also Read: Applied Quantum Computing: Unlocking the Power of the Quantum Realm

Conclusion

The Butler G4B25 is a cornerstone of industrial automation, offering unmatched precision, reliability, and versatility. Its ability to adapt to diverse tasks, combined with its robust construction, makes it an invaluable asset across various industries. Whether in assembly lines, robotics, or CNC machining, the G4B25 elevates operational efficiency and productivity. Investing in this component ensures a future-ready industrial setup, poised to meet the demands of modern manufacturing.